Hello Everyone!

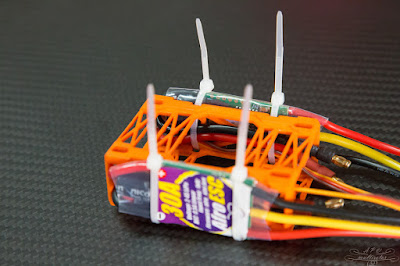

My second iteration of creating motor/ESC mount to hold two ESCs close to motors can be considered as successful. I'm impressed with OpenSCAD software which gave me quick and easy way to go from idea to real part.

Zip ties are used to keep ESCs and wires tight and no hang around

16mm tube clamp go in dedicated slots

Now we have motor mount plates bolted.

When all the wires and clumps are tied up together it's become easy to take out motor plate, swap motors and put everything back together. No worries that small pieces fall all over the place.

Here is "fully" assembled arm.

There is still work to be done like flip ESCs in way power and servo wires go straight inside tube. But next stem is to make small PCB where to connect everything and get least possible amount of copper through tube. Plus I like to have some LEDs on arms so need LED driver here as well.

Never ending game :)

My second iteration of creating motor/ESC mount to hold two ESCs close to motors can be considered as successful. I'm impressed with OpenSCAD software which gave me quick and easy way to go from idea to real part.

Zip ties are used to keep ESCs and wires tight and no hang around

16mm tube clamp go in dedicated slots

Now we have motor mount plates bolted.

When all the wires and clumps are tied up together it's become easy to take out motor plate, swap motors and put everything back together. No worries that small pieces fall all over the place.

Here is "fully" assembled arm.

There is still work to be done like flip ESCs in way power and servo wires go straight inside tube. But next stem is to make small PCB where to connect everything and get least possible amount of copper through tube. Plus I like to have some LEDs on arms so need LED driver here as well.

Never ending game :)

No comments:

Post a Comment